Discover how technology is revolutionizing laser performance across industries. This guide explains what beam shaping is, how beam shapers work, and why engineers should master this technique to improve precision, efficiency, and laser output quality.

In modern optics and photonics, beam shaping has become an essential process for engineers and scientists working with lasers. By carefully controlling the intensity, profile, and distribution of a laser beam, ensures that the output meets exact performance requirements. From medical lasers to industrial cutting tools, this technique can dramatically enhance accuracy and efficiency. If you want to revolutionize your laser, mastering beam shaping is the key.

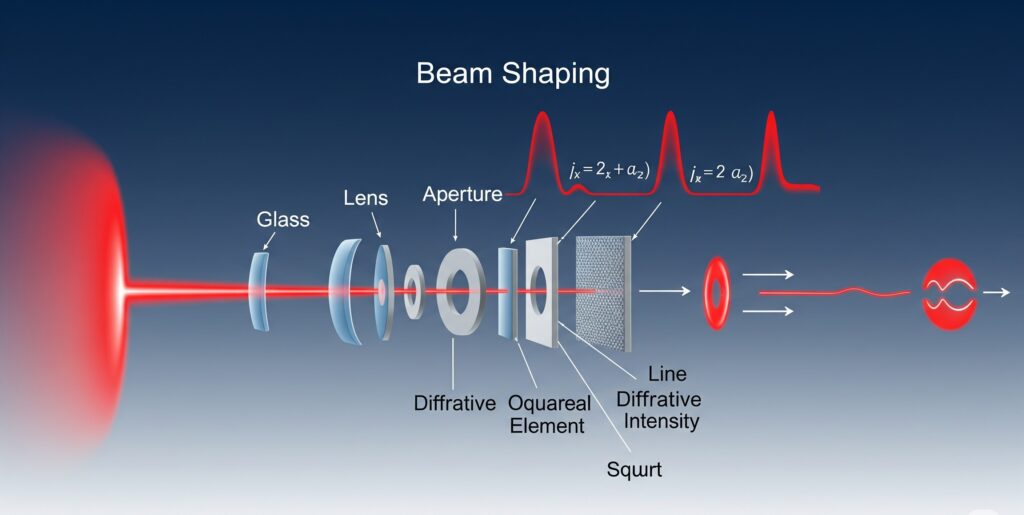

What is Beam Shaping?

Beam shaping refers to the process of transforming a laser beam from its natural Gaussian profile into a desired shape such as flat-top, square, rectangular, or other customized patterns. Traditional laser beams are not always suitable for advanced applications because of uneven power distribution. engineers can achieve beams with uniform energy density, reducing hot spots and improving precision.

Why Beam Shaping Matters for Engineers

- Precision & Accuracy – Uniform beams improve cutting, welding, and engraving quality.

- Efficiency – Less energy is wasted because the laser is shaped to match the task.

- Versatility – adapts lasers for different industries such as biomedical imaging, aerospace, semiconductor manufacturing, and 3D printing.

- Reliability – Reduced risk of overheating and longer system lifespan.

By applying engineers can transform a standard laser into a powerful, optimized tool.

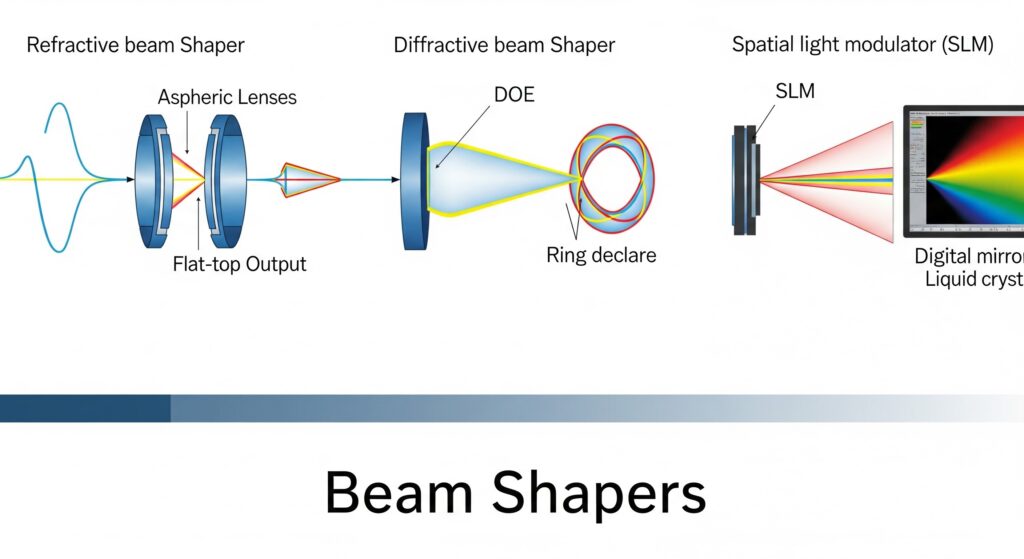

How Beam Shapers Work

Beam shapers are optical devices designed to redistribute the intensity of a laser beam. They use methods such as:

- Diffractive optics – Uses microstructures to shape the beam with high accuracy.

- Refractive optics – Relies on lenses to alter beam distribution.

- Hybrid systems – Combine both approaches for enhanced flexibility.

The result is a perfectly engineered laser output tailored for the task.

Applications of Beam Shaping

Beam shaping technology is revolutionizing multiple industries:

- Medical lasers – Precise tissue cutting with minimal damage.

- Industrial processing – Enhanced cutting, welding, and drilling efficiency for industrial applications.

- Semiconductors – Enhanced photolithography and wafer inspection.

- Research & Imaging – Uniform illumination for microscopy and spectroscopy.

- Additive manufacturing (3D printing) – Even energy distribution ensures stronger, defect-free structures.

Whether in research or production, It unlocks next-level performance.

Revolutionize Your Laser: The Ultimate Guide to Beam Shapers

If you are an engineer looking to upgrade your laser systems, beam shapers are the ultimate solution. They allow you to:

- Convert Gaussian beams into flat-top beams.

- Eliminate unwanted diffraction patterns.

- Maintain stability over long working distances.

- Improve laser-material interaction.

By integrating beam shaping into your systems, you can revolutionize your laser performance and stay ahead in competitive industries.

FAQs

Q1: What is the main purpose of beam shaping?

A: The primary goal is to achieve uniform energy distribution for higher precision and efficiency in laser applications.

Q2: What types of beam profiles can be created?

A: Engineers can shape beams into flat-top, square, rectangular, elliptical, or even custom profiles depending on the application.

Q3: How does beam shaping improve industrial laser cutting?

A: With beam shaping, energy is distributed evenly, preventing burns, reducing material waste, and ensuring cleaner cuts.

Q4: Are beam shapers only for industrial use?

A: No. Beam shaping is widely used in medical devices, scientific research, semiconductor manufacturing, and even defense technologies.

Q5: Do beam shapers affect laser power?

A: Beam shapers do not reduce power but redistribute it. This ensures more effective use of laser energy without loss of intensity.

Final Thoughts

For engineers, beam shaping is now a required skill, not a choice, especially in industries that demand high precision.By mastering and using advanced beam shapers, you can revolutionize your laser performance, reduce inefficiencies, and achieve breakthroughs in manufacturing, medicine, and research.

If you want your laser systems to deliver maximum accuracy and efficiency, then beam shaping is the ultimate key.